Non-magnetic splitter

Key words:

Application areas: industry, medical, mining, agriculture and logistics. The main functions are stamping, grinding, tracking, welding, machine tools, spraying, vision (precisely picking up items for flow work), die-casting, injection molding, assembly, etc.

Service content: Provide free consulting services, provide customized solutions, provide application guides, and maintain a 12-month maintenance period

Product highlights: It provides high-precision and flexible operation, can automate the production process, and improve production efficiency; it also has a safe and reliable design, reduces operational risks, and brings sustainable development solutions to the production environment.

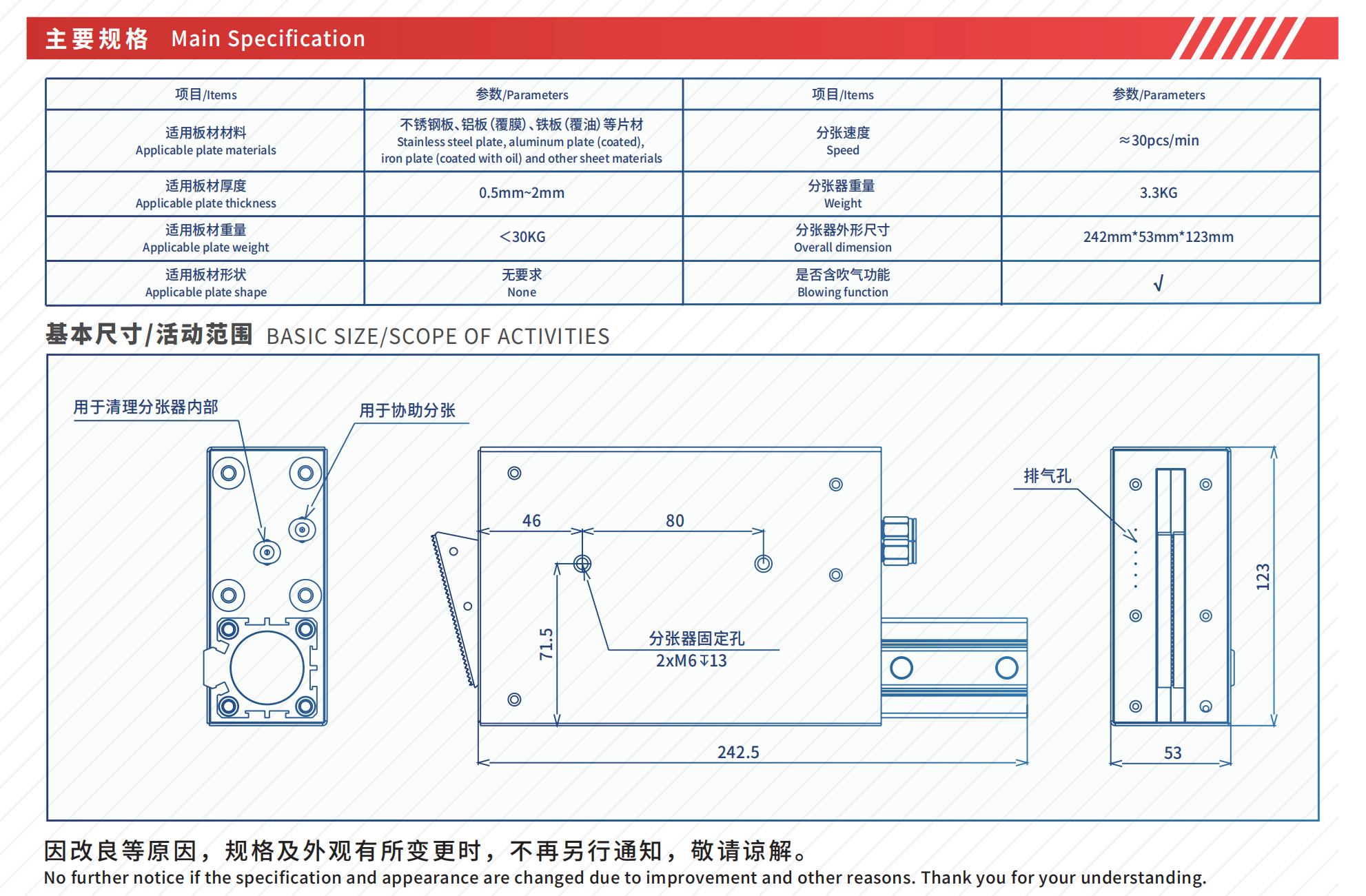

This company non-magnetic splitter can be used in automated scenarios such as stamping, bending, or other sheet materials that require separation. Its applicable plates include stainless steel plate, alumi-num plate, plastic plate, metal plate with oil or film coating on the surface, etc. Using mechanical split-ting, the main push rod is pushed by a cylinder to achieve splitting. The main push rod is equipped with racks, and the tooth pitch varies according to the thickness of the plate. The main push rod has the freedom to move vertically upwards, and when the cylinder pushes the rack through the main push rod to contact the sheet metal, it can freely separate only the first sheet metal and achieve separation.

Online consultation